With many years of experience in production management and quality control, Master Phan Trọng Nhân is a consulting expert partnering with Gia Phat Dehumidifier Joint Stock Company. From optimizing production lines and implementing 5S-3D training to strictly controlling output product quality, the expert’s partnership has made a significant contribution to helping Gia Phat elevate its operational efficiency and brand reputation in the market.

Master Phan Trọng Nhân is a consulting expert trained and directly involved in business consulting within the framework of the “Training Program for Vietnamese Consultants,” implemented by the Ministry of Industry and Trade in collaboration with Samsung Vietnam. Through this program, the expert has accumulated practical experience and modern approaches, helping Vietnamese businesses improve production efficiency and enhance product quality according to international standards.

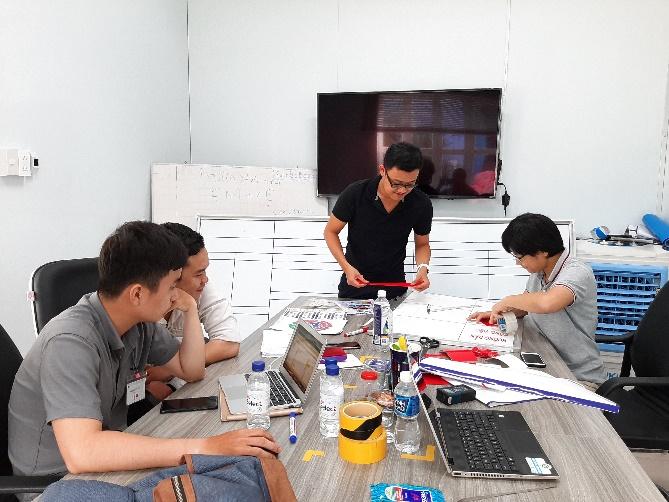

Figure 1. Consulting expert Master Phan Trọng Nhân partnering with Gia Phat Dehumidifier Joint Stock Company.

The consulting expert, Master Phan Trọng Nhân, along with the consulting team, not only delivered theoretical training sessions or strategic consultations but also directly partnered with and worked alongside the company daily, continuously for a full month. Every production stage, every step of transformation, and every process refinement was closely guided and supervised by the expert, helping the company not only to understand but also to practice and sustain the changes effectively.

Figure 2. Strategic consulting sessions with the leadership and staff of Gia Phat.

At Gia Phat Dehumidifier Joint Stock Company, Master Phan Trọng Nhân consulted on and directly participated in key activities, including:

🏭 Optimizing the Production Line:

Reduce Waste – Increase Productivity – Save Costs

The expert, along with the technical team, reviewed the entire production process, identified bottlenecks and waste, and proposed improvement solutions. The results included a leaner process, increased production speed, reduced defects, and cost savings.

Figure 3. Reviewing and optimizing the production process.

🧹 Training & Implementing 5S – 3D

Building a Professional, Clean, and Scientific Work Environment

With an approachable, lively training method that involved hands-on practice right in the workshop, Master Nhân helped Gia Phat’s managers and workers understand and master the 5S – 3D methodology, thereby creating a professional, clean, and scientific work environment. This also serves as the foundation for the company’s long-term growth.

Figure 4. Training and application activities for 5S – 3D.

✅ Controlling Output Product Quality

Establishing Strict Control Processes, Reducing Defects, Enhancing Product Reputation

Quality is a vital factor for a manufacturing business. Master Nhân provided consultancy on building a strict quality control system, featuring a multi-layered inspection process and root cause analysis for common defects. As a result, the rate of defective products decreased significantly, helping Gia Phat strengthen its reputation with customers and partners.

Figure 5. Activities for controlling output product quality.

With the dedicated partnership of Master Phan Trọng Nhân and the consulting team, and the unified effort of the entire Board of Directors and staff, Gia Phat Dehumidifier Joint Stock Company has not just stopped at immediate improvements but is also building a solid foundation for long-term, sustainable development. From changing mindsets and standardizing processes to spreading the spirit of continuous improvement throughout the team, all these efforts are helping to advance Gia Phat on its journey to enhance product quality and affirm its market position.